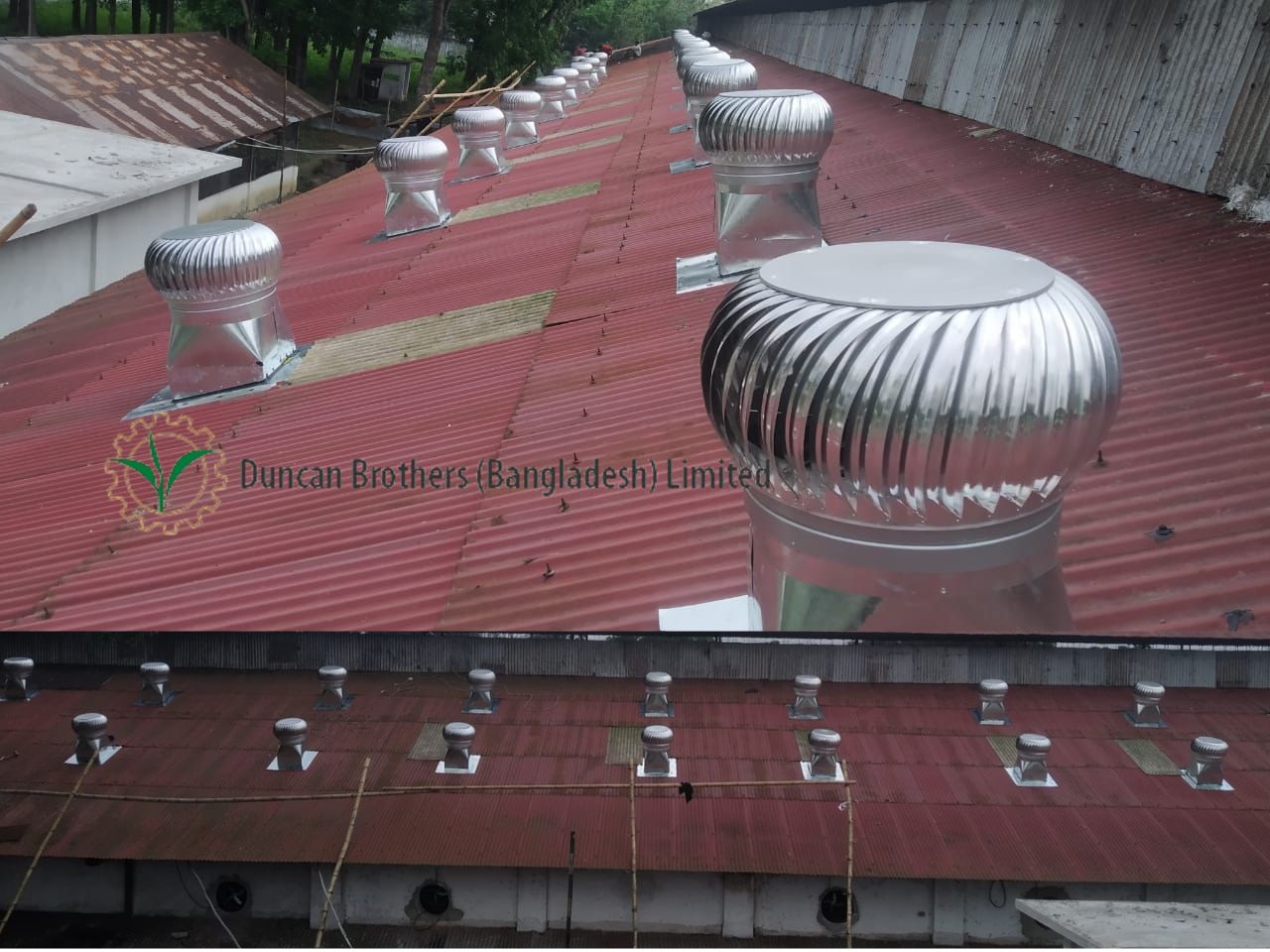

Working Procedure

The turbine ventilator operates by utilizing the velocity energy of the win d to induce air flow by centrifugal action. The centrifugal force caused by the spinning vanes creates a region of low pressure area which draws air out through the turbine. Air drawn out by the turbine is continuously replaced by fresh air from the outside. The slightest breeze will cause the turbine to spin and even otter the breeze has stopped, the fly wheel effect of the rotor cage will use its stored energy for continuously remove air giving rise to ventilation. Suction is maintained even at low wind velocities

| Type of building | Air Chang as per hour | Type of bu ilding | Air Changes per hour |

| Factories (Heavy) | 10-30 | Paper Mill | 8-30 |

| Boiler room | 10-30 | Textile Mill | 4-12 |

| Pocking room | 8-30 | Trans former room | 12 -30 |

| Engine room | 12-30 | Pain t shops | 10-30 |

| Factories (light) | 6-12 | Warehouse | 4-6 |

| Type of building | Air Chang as per hour |

| Factories (Heavy) | 10-30 |

| Boiler room | 10-30 |

| Pocking room | 8-30 |

| Engine room | 12-30 |

| Factories (light) | 6-12 |

| Paper Mill | 8-30 |

| Textile Mill | 4-12 |

| Trans former room | 12 -30 |

| Pain t shops | 10-30 |

| Warehouse | 4-6 |

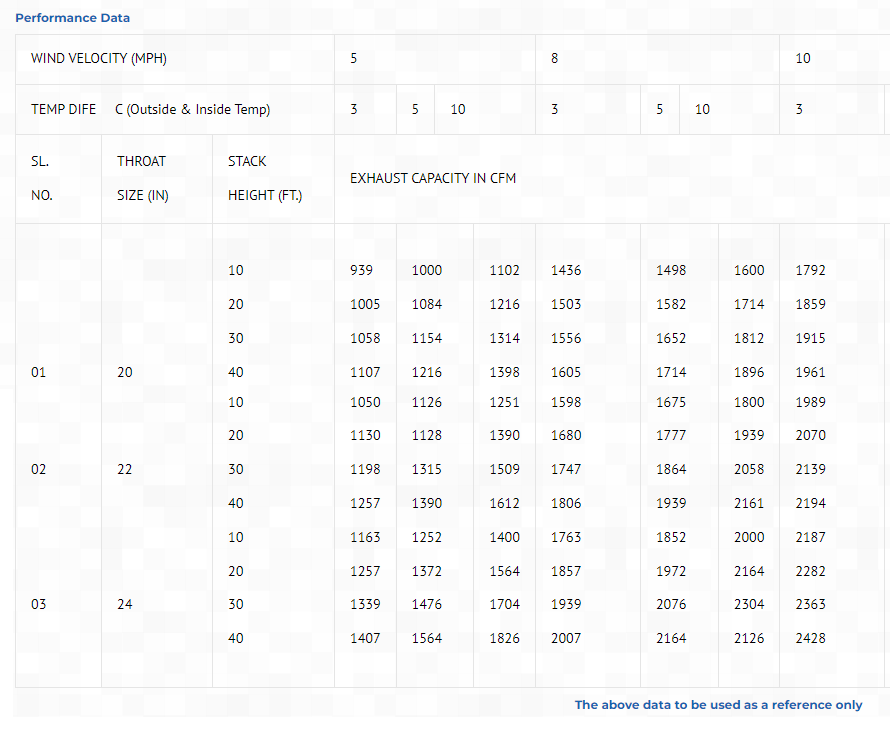

| WIND VELOCITY (MPH) | 5 | 8 | 10 | |||||||||||||||

| TEMP DIFE C (Outside & Inside Temp) | 3 | 5 | 10 | 3 | 5 | 10 | 3 | 5 | 10 | |||||||||

SL. NO. | THROAT SIZE (IN) | STACK HEIGHT (FT.) | EXHAUST CAPACITY IN CFM | |||||||||||||||

01

02

03 |

20

22

24 | 10 20 30 40 10 20 30 40 10 20 30 40 | 939 1005 1058 1107 1050 1130 1198 1257 1163 1257 1339 1407 | 1000 1084 1154 1216 1126 1128 1315 1390 1252 1372 1476 1564 | 1102 1216 1314 1398 1251 1390 1509 1612 1400 1564 1704 1826 | 1436 1503 1556 1605 1598 1680 1747 1806 1763 1857 1939 2007 | 1498 1582 1652 1714 1675 1777 1864 1939 1852 1972 2076 2164 | 1600 1714 1812 1896 1800 1939 2058 2161 2000 2164 2304 2126 | 1792 1859 1915 1961 1989 2070 2139 2194 2187 2282 2363 2428 | 1854 1938 2010 2070 2065 2167 2255 2328 2276 2396 2500 2586 | 1958 2070 2168 2252 2191 2328 2448 2551 2424 2586 2728 2850 | |||||||

Advantages

| Size Ø (A) | Number of blades | Blade DiameterØ (B) | Weight (kg) | The efficiency of the ventilation(Average speed 6 Miles /Hour) |

| 22” | 36” | 28” | 7.2 | 170,000 CFH |

| 25” | 42” | 30” | 8.2 | 190,000 CFH |

Size Ø (A) |

|

22” | |

25” | |

Number of blades |

|

36” | |

42” | |

Blade DiameterØ (B) |

|

28” | |

30” | |

Weight (kg) |

|

7.2 | |

8.2 | |

The efficiency of the ventilation(Average speed 6 Miles /Hour) |

|

170,000 CFH | |

190,000 CFH |

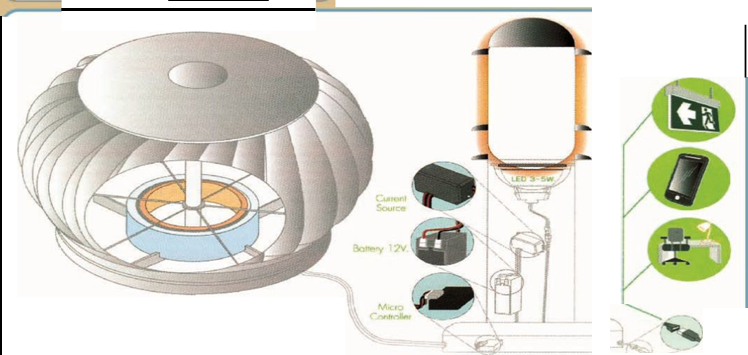

New Valued Added of New

Energy Ventilator (NEV)

- Ability to generate electrical power by natural wind and store in batte The system will give you a various advantages such as LED Lighting, battery charger, mobile phone charger, emergency light and etc.

- When the absence of wind, the system will return an electrical power from battery back to motorize fan itself.

- It said that “NEV is a never stop ventilator”

Eco-friendly Product

- Renewable Energy:

- Sustainable or Alternative Energy:

- Emergency Energy:

Maximum Power (95 w)

Technical Specification

- Starting Wind…………………………….. 1 m/sec

- Cut in Wind……………………………….. 2 m/s

- Highest Rated Wind…………………… 13

- Average Wind……………………………. 5 m/se

- Maximum Power……………………….. 95 w

- Ventilator diameter……………………. 25 inches